Efficiency and Productivity Amplified with Sylcom:

Comprehensive Regulatory Traceability

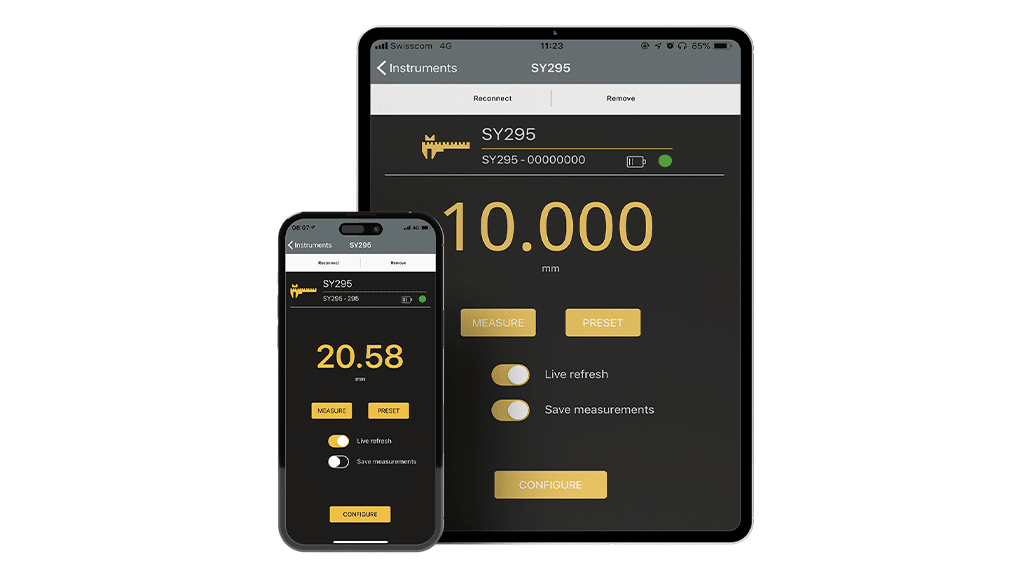

Sylcom empowers manufacturing companies to achieve seamless regulatory compliance through comprehensive traceability. Meet stringent industry requirements by effortlessly adding traceability to every measurement.

Capture essential data such as instrument models, references, colors, factory details, operator information, shift details, CNC machine associations, and more. Sylcom’s robust traceability features save time and effort in meeting regulatory demands, ensuring your quality control process is on track.

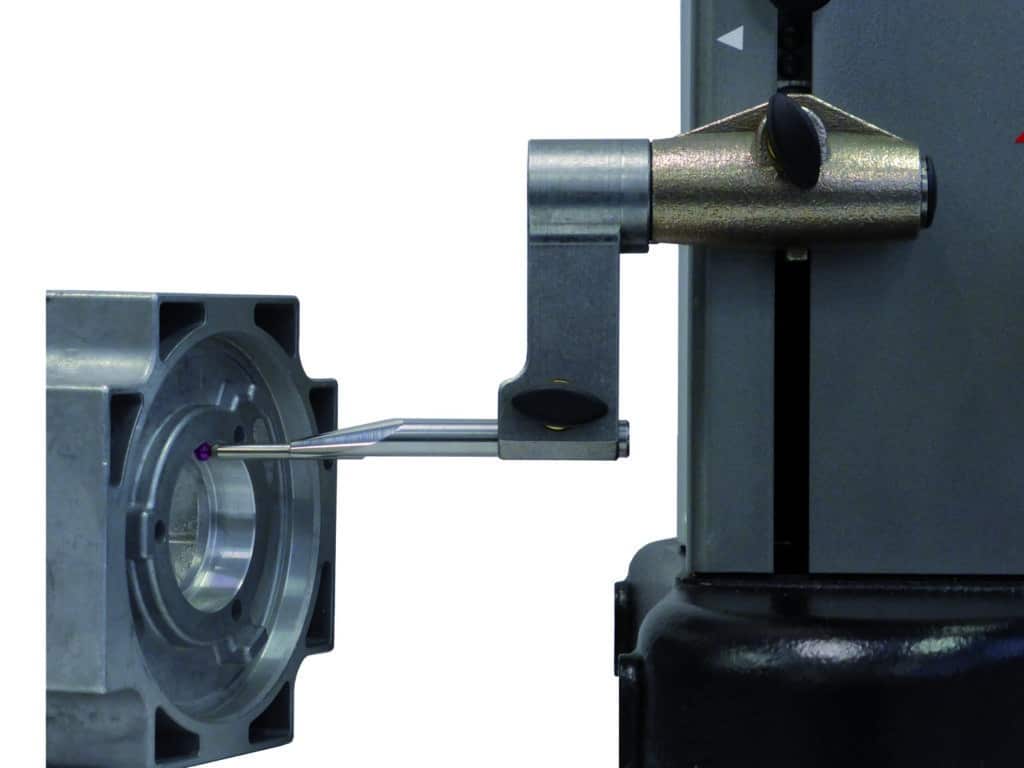

Timely Calibration Tracking

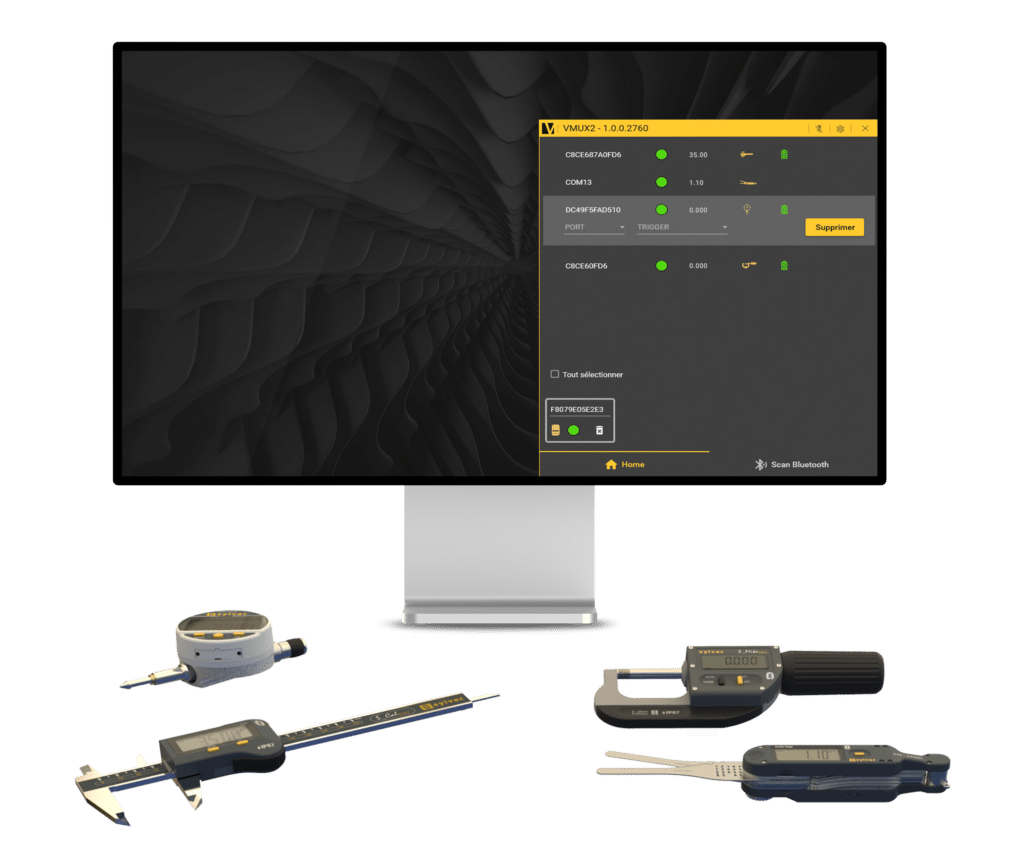

Precision is key in manufacturing, and Sylcom simplifies the process of maintaining accurate measurements. Monitor calibration schedules for your Sylvac instruments with ease. Stay ahead of calibration requirements, plan efficiently, and avoid costly downtime. With Sylcom, your manufacturing processes remain operational, accurate, and efficient through timely calibration.

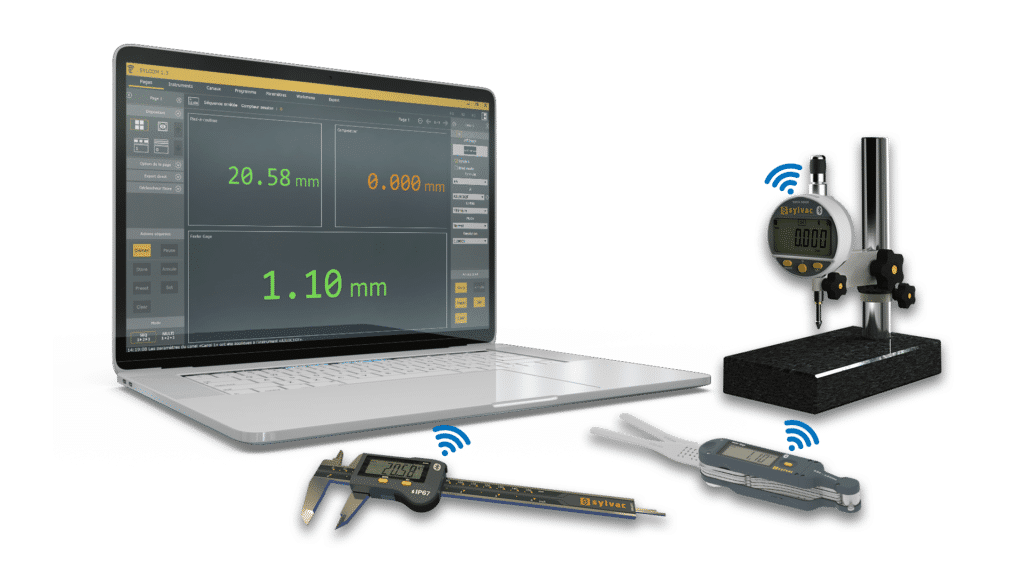

Peak Instrument Performance

Sylcom’s calibration tracking capabilities keep your instruments performing at their best. Stay informed about calibration dates for your Sylvac instruments to plan calibrations effectively and reduce the risk of inaccurate measurements and disruptions. With Sylcom’s user-friendly interface, you gain control over both regulatory traceability and calibration needs, streamlining your quality control processes and driving overall manufacturing efficiency.