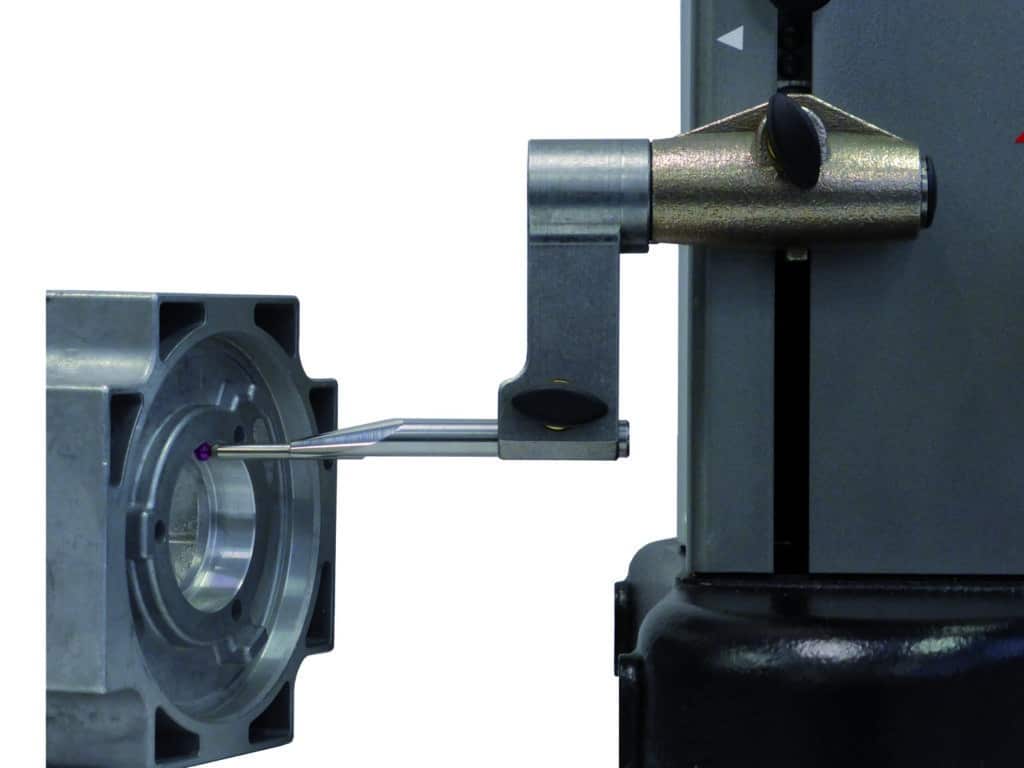

In the past, Quality Assurance Managers faced the daunting task of creating control plans and other configurations on individual PCs across the workshop floor. This time-consuming process often led to inefficiencies and inconsistencies in quality control. However, with Sylvac’s Sylcom software, those days are a thing of the past.

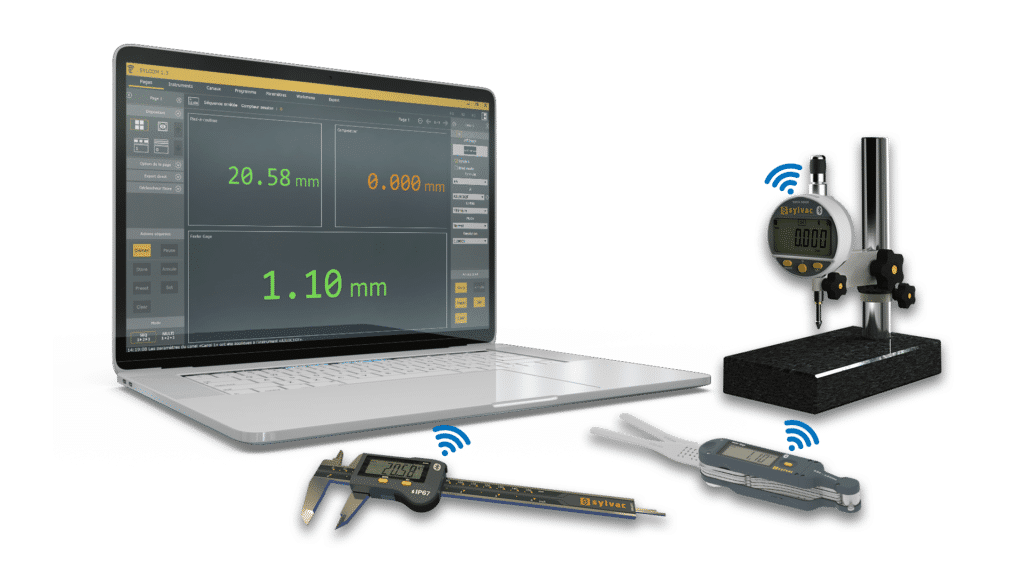

Seamless Control Plan Deployment

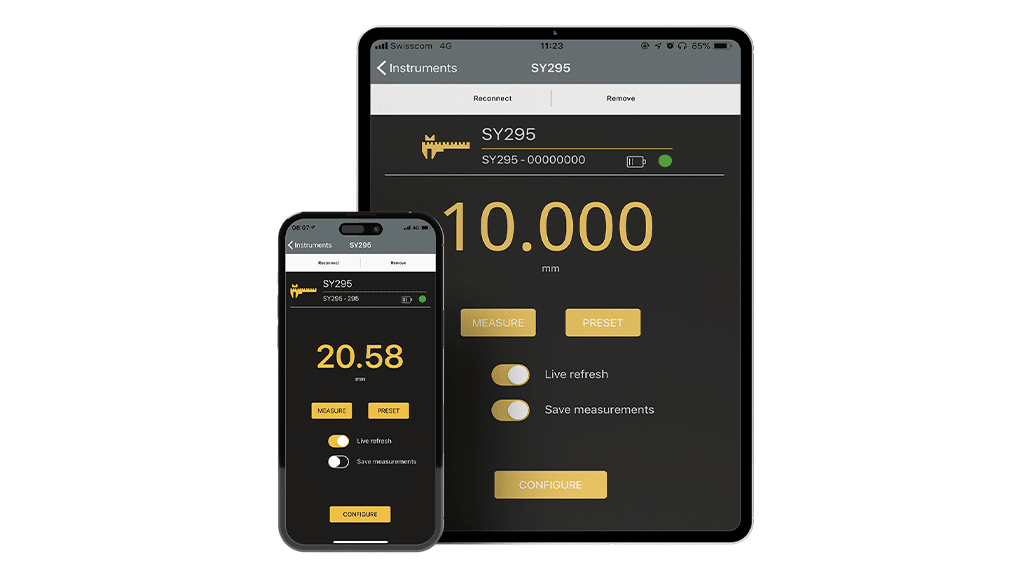

Sylcom’s remote control capabilities empower Quality Assurance Managers to create control plans from the comfort of their office. With just a few clicks, a comprehensive control plan can be designed and effortlessly sent to all PCs on the workshop floor. This seamless deployment ensures that all production teams are working with the latest and most up-to-date quality control instructions.

Real-Time Updates for Consistent Quality

As the production process evolves and new insights arise, Quality Assurance Managers can instantly update and modify control plans remotely. These real-time updates can be communicated to all PCs on the workshop floor, ensuring consistent quality control measures across all stages of manufacturing.

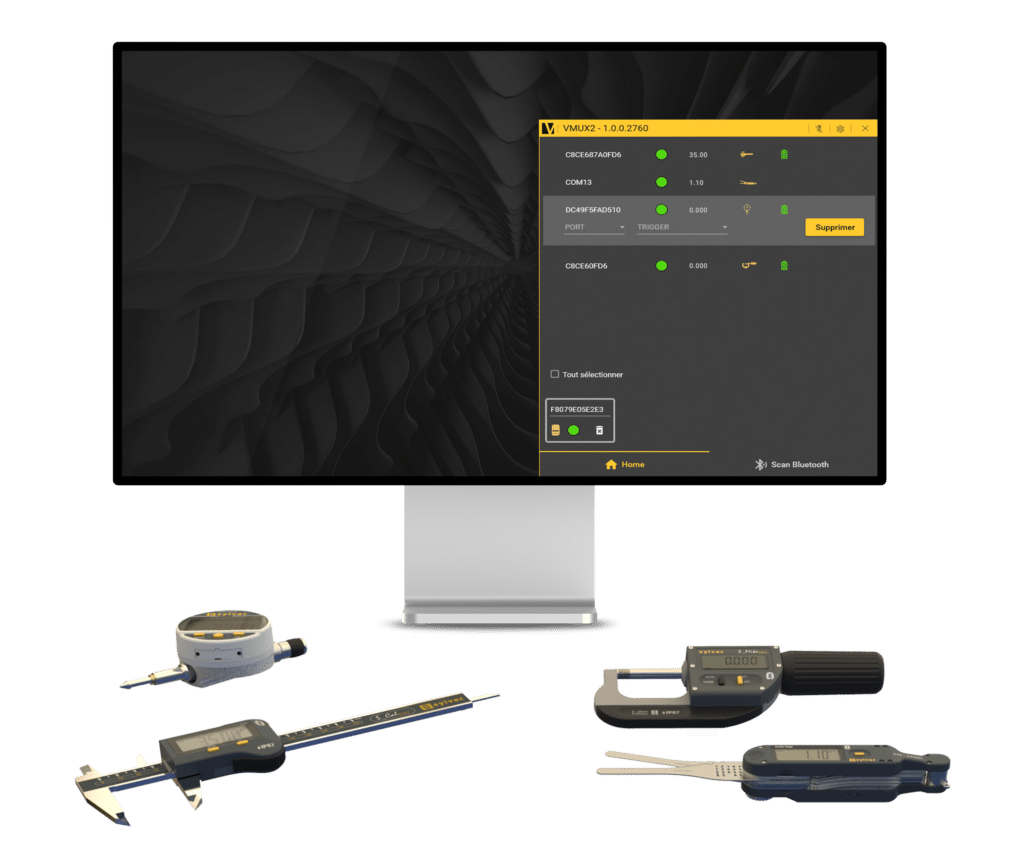

Centralized Quality Assurance Management

Sylcom’s remote control functionality centralizes quality assurance management, providing a single platform for Quality Assurance Managers to oversee and monitor quality control activities. No longer burdened with managing multiple PCs, managers can efficiently handle quality assurance tasks from one location.

Enhanced Data and Reporting

Sylcom’s remote capabilities also offer in-depth data and reporting features. Quality Assurance Managers can access real-time data on quality control processes, identify trends, and make data-driven decisions to optimize productivity and quality.

Optimize Efficiency and Productivity

By leveraging the remote control abilities of Sylcom, Quality Assurance Managers can focus on strategic planning and process improvement, rather than being bogged down by manual control plan deployment. This optimized efficiency leads to increased productivity and reduced production downtime.