Optimizing Manufacturing Processes for Superior Results

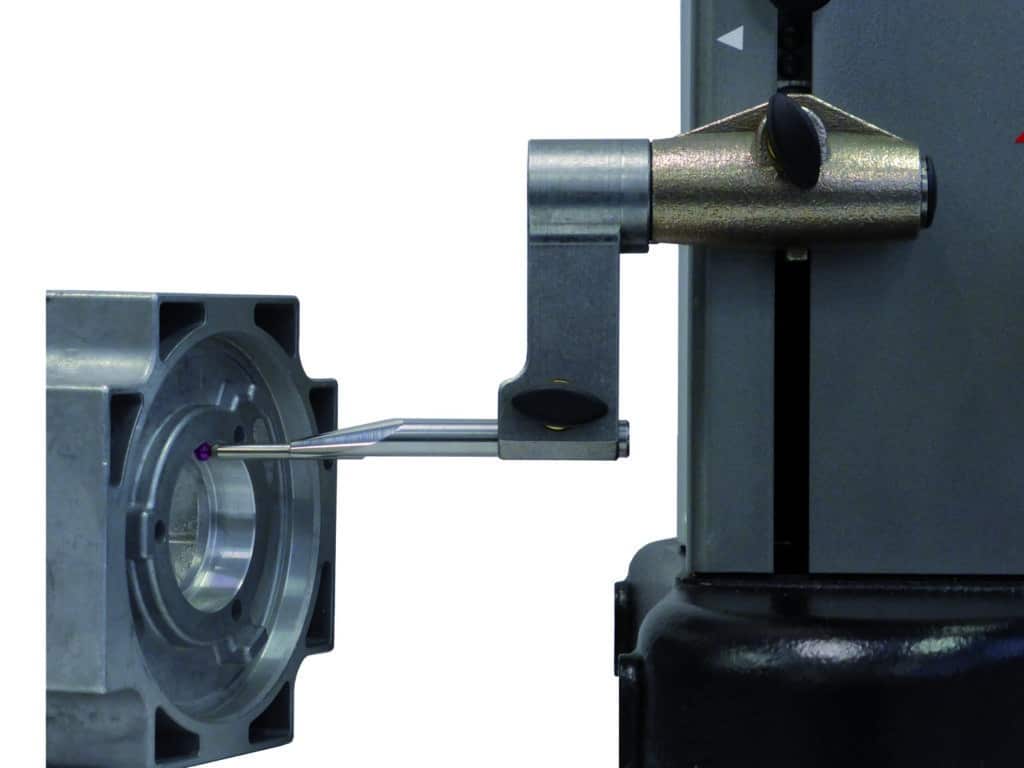

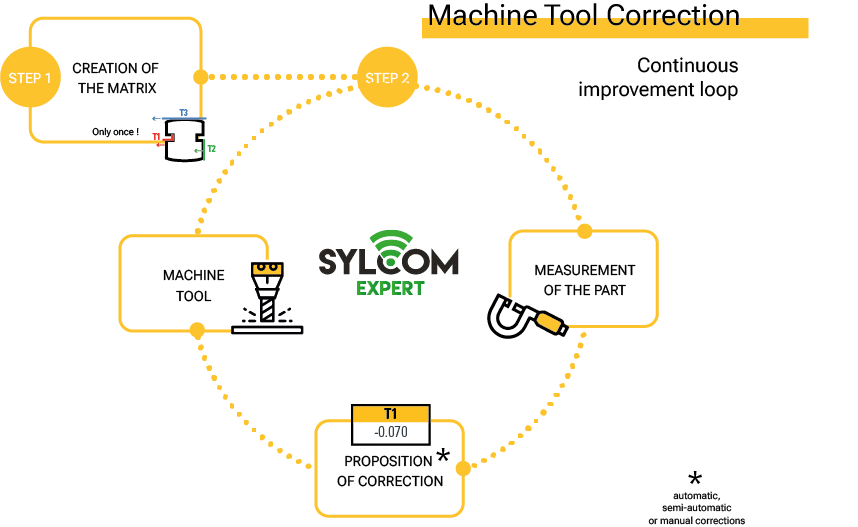

The Machine Tool Correction (MTC) feature offered by Sylvac is a game-changer for companies striving to optimize the performance of their manufacturing workshops. MTC provides a valuable solution by suggesting tool corrections following the detection of deviations during the measurement stage of the machining process. This capability aids in decision-making for operators, allowing them to center the machined dimensions effectively.

How does it work?

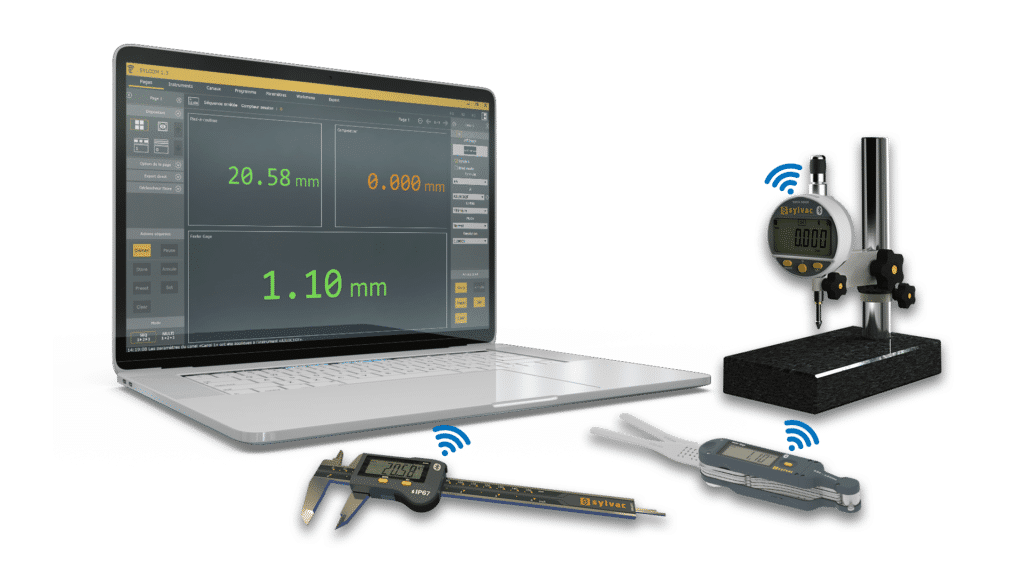

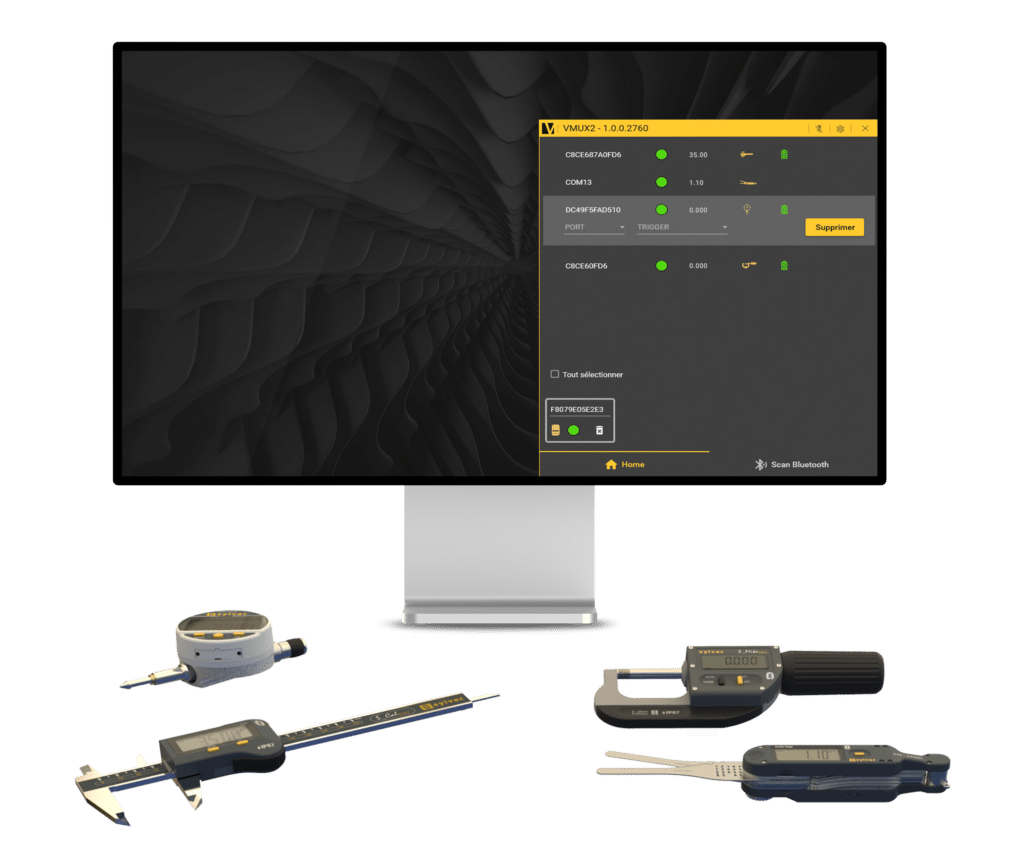

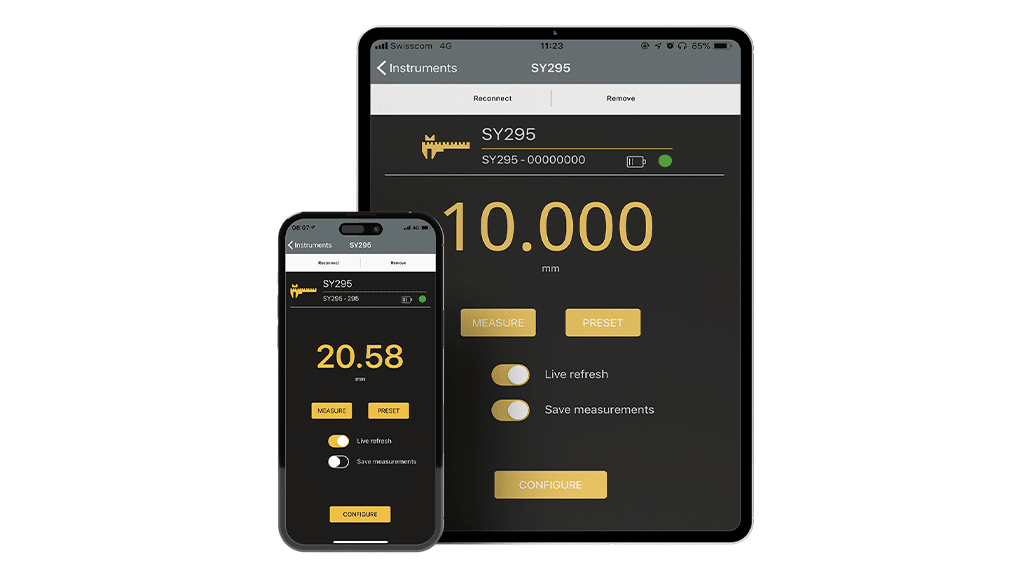

The MTC feature functions by monitoring the measurements of the parts being machined. Through the powerful Sylcom software, deviations from the nominal values are detected. When such deviations occur, the MTC feature suggests correction recommendations that can be implemented automatically, semi-automatically or manually.

Customer Benefits

Implementing MTC within your manufacturing processes brings forth a multitude of benefits that positively impact your operations, efficiency, and product quality.

1. Centering the Machining Process

MTC provides a valuable aid in centering the machining process by detecting deviations and suggesting corrections. This results in improved dimensional accuracy and helps achieve consistent and reliable manufacturing outcomes.

2. Minimized Waste

By promptly detecting deviations and recommending corrections, MTC minimizes waste in the production process. By addressing issues in real-time, MTC reduces the likelihood of producing defective products, optimizing material utilization, and reducing overall waste generation.

3. Reduced Setup Time

MTC’s ability to suggest tool corrections in real-time reduces setup time, streamlining the production process. By swiftly identifying and addressing deviations, operators can make necessary adjustments promptly, minimizing downtime and improving overall production efficiency.

4. Increased Productivity

With MTC, your production processes become more efficient, leading to increased productivity. By continuously monitoring and adjusting the machining process, MTC minimizes downtime, enhances throughput, and ensures optimal utilization of resources.