Menu

Close

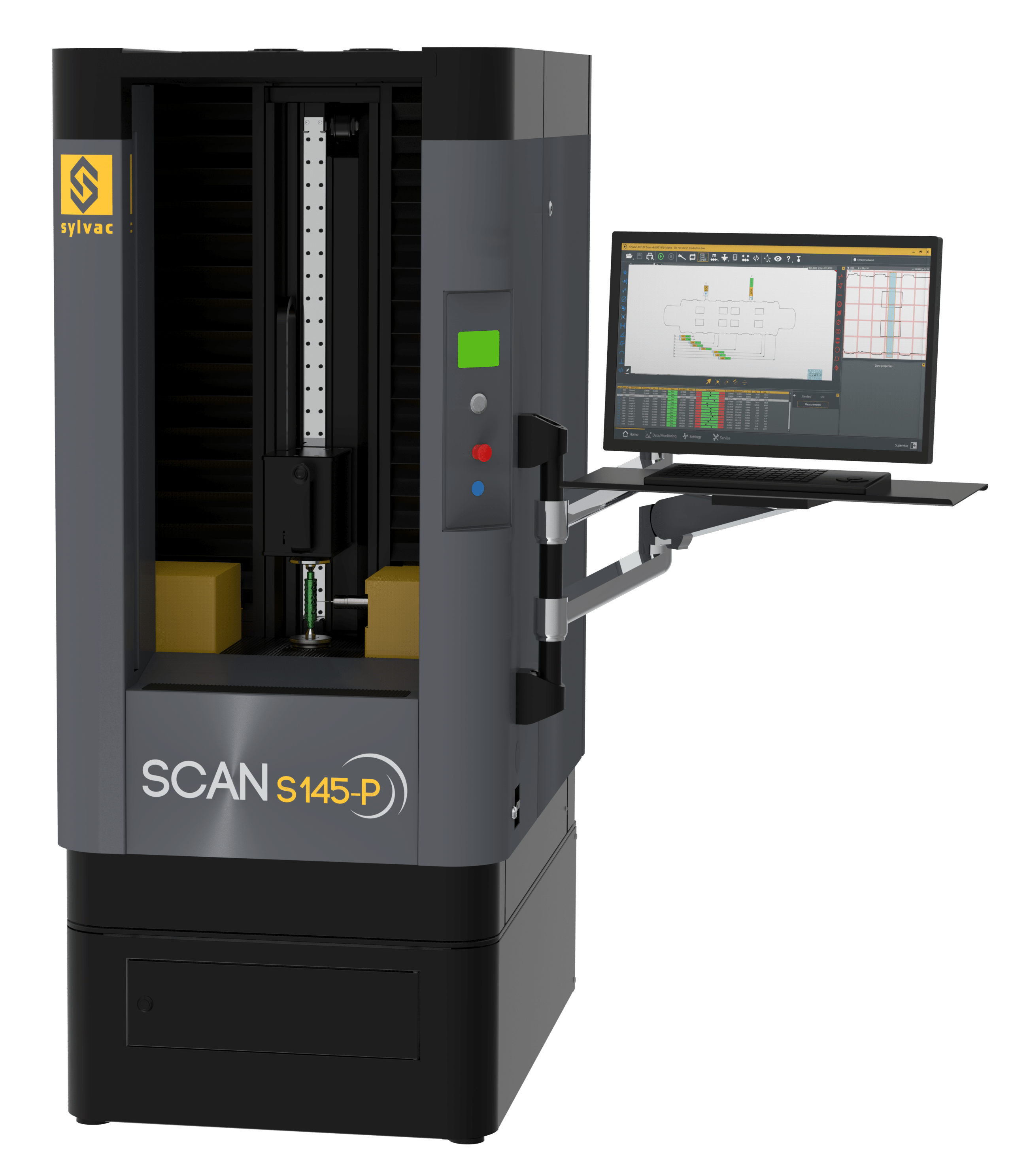

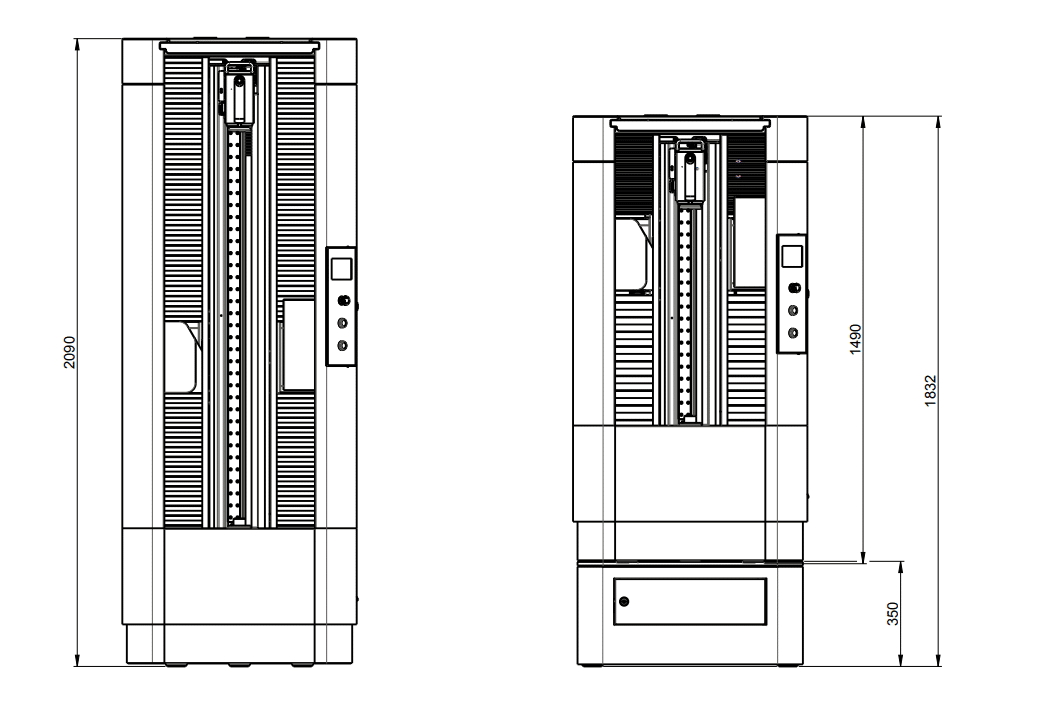

Optical measurement SYLVAC-SCAN S145-P

Description

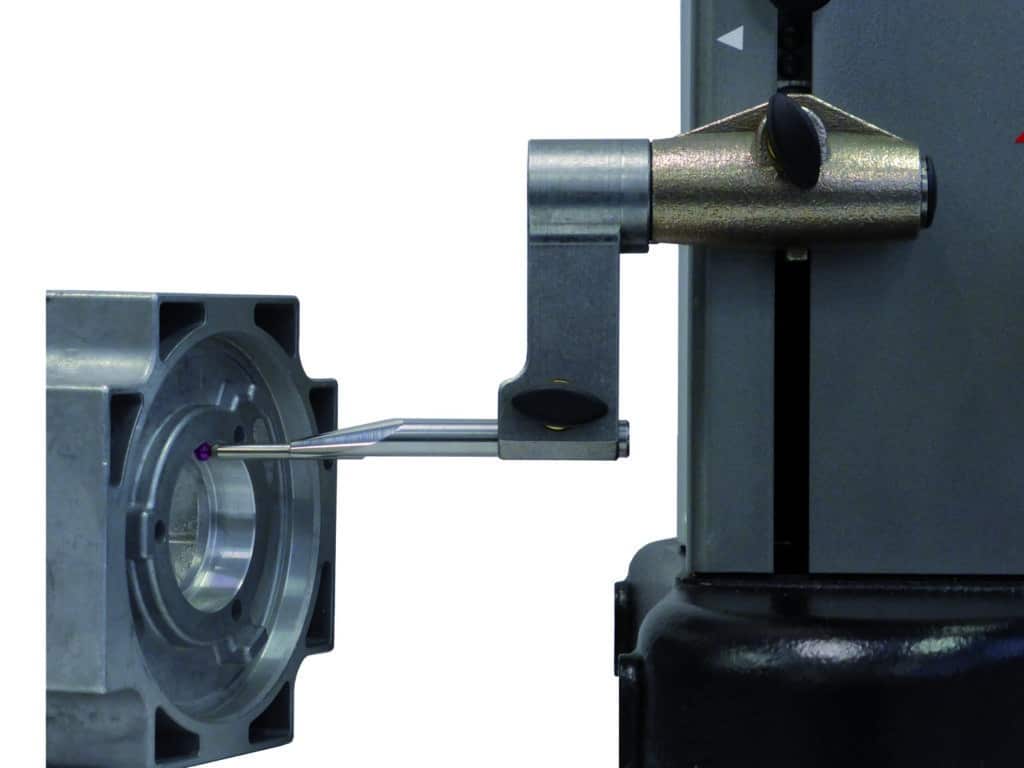

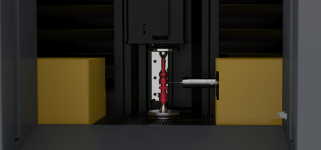

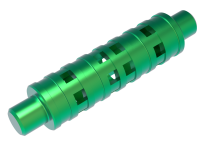

New application with 3D probe : the addition of the Renishaw SP25M probe offers a multi- sensor solution for characteristics not visible with optics.

*Available in different measuring ranges

*Available in different measuring ranges

Swiss made

0.1µm

Cable

Features

- All in one solution: Complete measurement with a single system, seamless integration with combined sensor measurements, easy programming thanks to user-friendly functions, full touch probe scanning capability for measuring form, interchangeable probe stylus increased access, automated probe qualification routine and typical measurements include : hole and slot size, location and form, roundness, radial and axial runout.

- Cost Savings at Every Turn: Our non-contact machine is designed for the measurement of large cylindrical parts up tp 100kg. One of our machine can handle virtually all measurements (static and dynamic) on cylindrical parts up to 145mm wide and 615mm long. With a complete 2D part scan taking less than 3 seconds, you can reduce inspection time, minimize scrap, and increase overall productivity.

- Intuitive Operation: Enjoy easy operation right at your workplace with the new touch screen control panel. The dynamic LED indicator and intuitive Reflex SCAN+ concept provide real-time feedback on the measured part’s status (GO/NG) and operator messages. No prior programming is required—just a simple touch-button solution.

- Precision and Efficiency: Experience exceptional precision with our no-contact machine’s bi-telecentric optical system and high-resolution CMOS camera. It features a precision sliding headstock with an integrated and protected daily standard, as well as a quick and hassle-free accessory changing system. The machine also includes integrated temperature sensors and exists with or without tilt system for true comprehensive thread measurement.

- Seamless Integration: Our offering includes the Reflex SCAN+ software and a PC, empowering you to effortlessly measure a wide range of elements in an intuitive manner. Also available with ‘Automation Ready’ configuration upon request, to seamlessly integrate into your workflow.

Applications

Diameter

Distance

Angle

Localisation

Form deviation

Industries

Automotive

Aeronautics

Fastening

Packaging

Machine tool

Overview

Specifications

Standard Delivery

Accessories

Applications

Tutorials

Documents

| 902-4145-05 | 902-4147-05 |

902-4148-05 | ||||

| EAN | 7640125698091 | 7640125697131 | 7640125698107 | |||

| Diameter | Length | Diameter | Length | Diameter | Length | |

| Measuring range (mm) | 145 | 615 | 145 | 1230 | 145 | 1750 |

| Resolution up to (mm) | 0.0001 | |||||

| Max. error (µm) | 1.5 + (D[mm]/100) ¹ / 4 + (L[mm]/200) ¹ | |||||

| Repeatability 2δ (µm) | 0.5 | 1.0 | 0.5 | 1.0 | 0.5 | 1.0 |

| Holding capacity (mm) | 200 ² | 615 | 200 ² | 1230 | 200 ² | 1750 |

| Axial positioning speed (mm/s) | Up to 160 | |||||

| Measuring volume of probe (mm) | PX : 615 / PY : +60, -40 / PZ : +130, -15 | |||||

| Max. weight of part (kg) | 100 | |||||

| Machine’s weight (kg) | 550 | 670 | 817 | |||

¹ 20° C ± 1° C

² with 3D probe

|

Standard Delivery

|

| Instrument according to technical specifications as standard machine |

| 1x SM25-1 Scanning module (902-5002) |

| 2x SH25-1 Stylus holder (902-5003) |

| 1x Ø1.5 mm x L30mm stylus (M3) (902-5010) |

-

Sylvac SCAN S145

Short presentation of Sylvac SCAN S145

-

Sylvac SCAN S145 & S145L

Discover the optical machines Sylvac SCAN S145 & S145L

-

How to measure with SCAN S145 & Robot

Fully automatised optical machine Sylvac SCAN S145 with universal robot

-

SYLVAC Scan Range - Full

Discover Sylvac and our Scan Range - the ultimate measurement solution for cylindrical parts

-

Sylvac SCAN S145-P

Discover the optical machines Sylvac SCAN S145-P

- Technical Plan

- 3D Drawing

- Manual

- Certificate

- Brochure

Spécifications

| 902-4145-05 | 902-4147-05 |

902-4148-05 | ||||

| EAN | 7640125698091 | 7640125697131 | 7640125698107 | |||

| Diameter | Length | Diameter | Length | Diameter | Length | |

| Measuring range (mm) | 145 | 615 | 145 | 1230 | 145 | 1750 |

| Resolution up to (mm) | 0.0001 | |||||

| Max. error (µm) | 1.5 + (D[mm]/100) ¹ / 4 + (L[mm]/200) ¹ | |||||

| Repeatability 2δ (µm) | 0.5 | 1.0 | 0.5 | 1.0 | 0.5 | 1.0 |

| Holding capacity (mm) | 200 ² | 615 | 200 ² | 1230 | 200 ² | 1750 |

| Axial positioning speed (mm/s) | Up to 160 | |||||

| Measuring volume of probe (mm) | PX : 615 / PY : +60, -40 / PZ : +130, -15 | |||||

| Max. weight of part (kg) | 100 | |||||

| Machine’s weight (kg) | 550 | 670 | 817 | |||

¹ 20° C ± 1° C

² with 3D probe

Standard Delivery

|

Standard Delivery

|

| Instrument according to technical specifications as standard machine |

| 1x SM25-1 Scanning module (902-5002) |

| 2x SH25-1 Stylus holder (902-5003) |

| 1x Ø1.5 mm x L30mm stylus (M3) (902-5010) |

Accessories

Tutorials

-

Sylvac SCAN S145

Short presentation of Sylvac SCAN S145

-

Sylvac SCAN S145 & S145L

Discover the optical machines Sylvac SCAN S145 & S145L

-

How to measure with SCAN S145 & Robot

Fully automatised optical machine Sylvac SCAN S145 with universal robot

-

SYLVAC Scan Range - Full

Discover Sylvac and our Scan Range - the ultimate measurement solution for cylindrical parts

-

Sylvac SCAN S145-P

Discover the optical machines Sylvac SCAN S145-P

Documents

- Technical Plan

- 3D Drawing

- Manual

- Certificate

- Brochure