Tailored and trustworthy Final Inspection

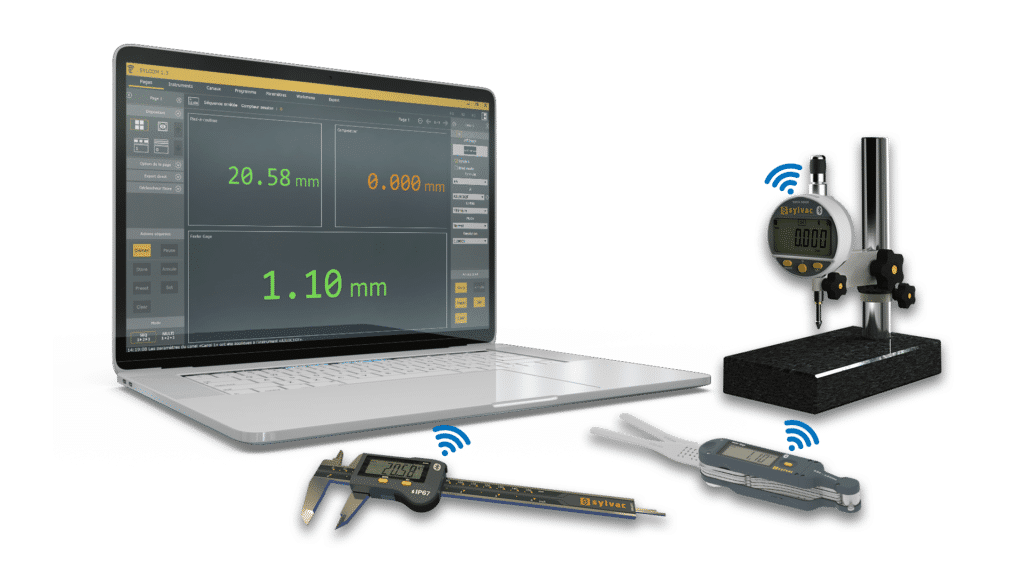

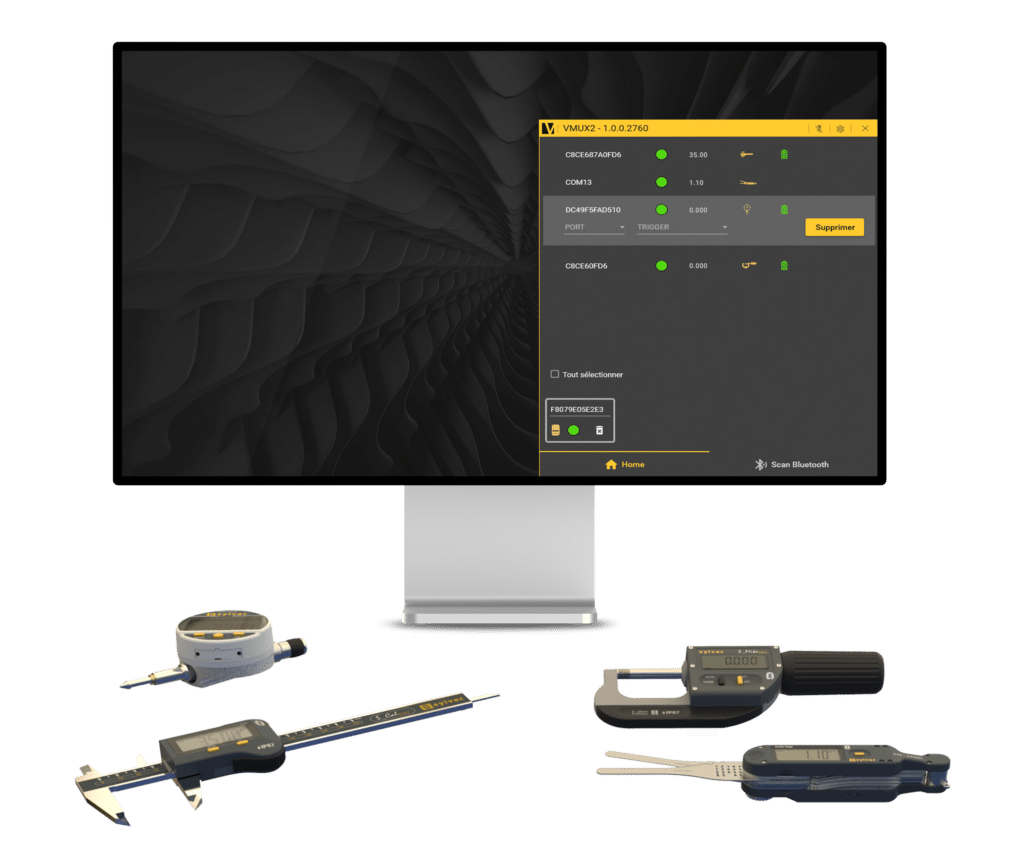

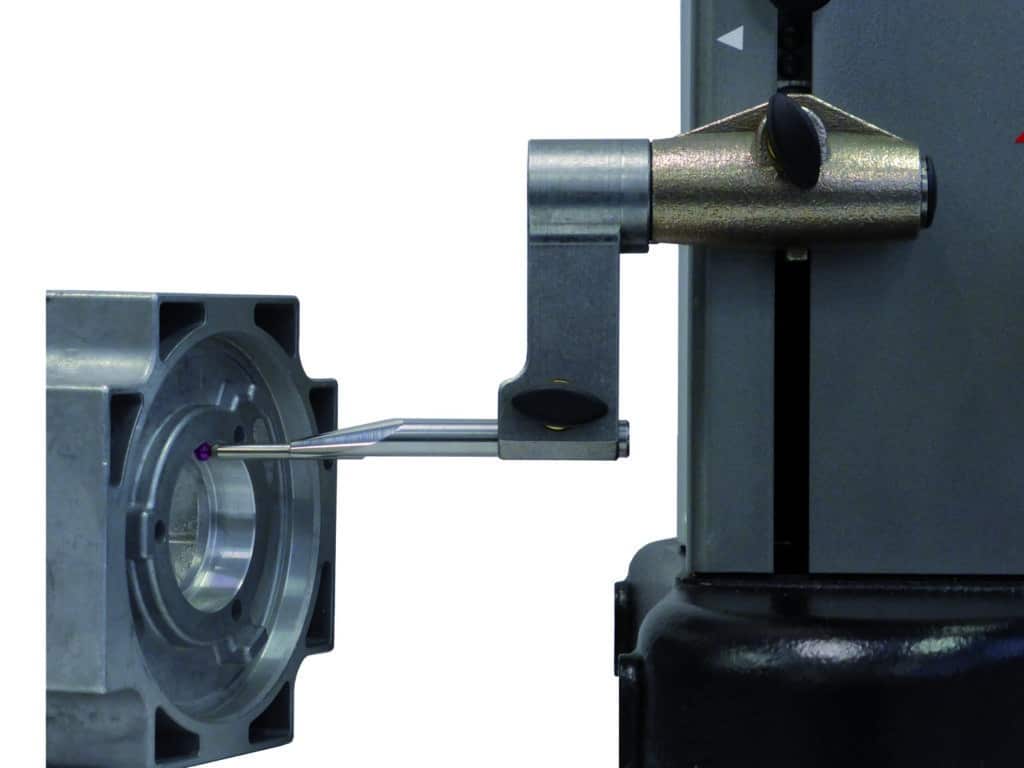

For companies who do perform full final inspection, Sylvac is here to support you with a two-fold approach. Firstly, we provide top-quality, robust, and accurate dimensional check instruments. Secondly, with our innovative Sylcom software, we offer the flexibility to incorporate dimensional and non-dimensional measures directly into your control plans.

Comprehensive Support with Quality Instruments

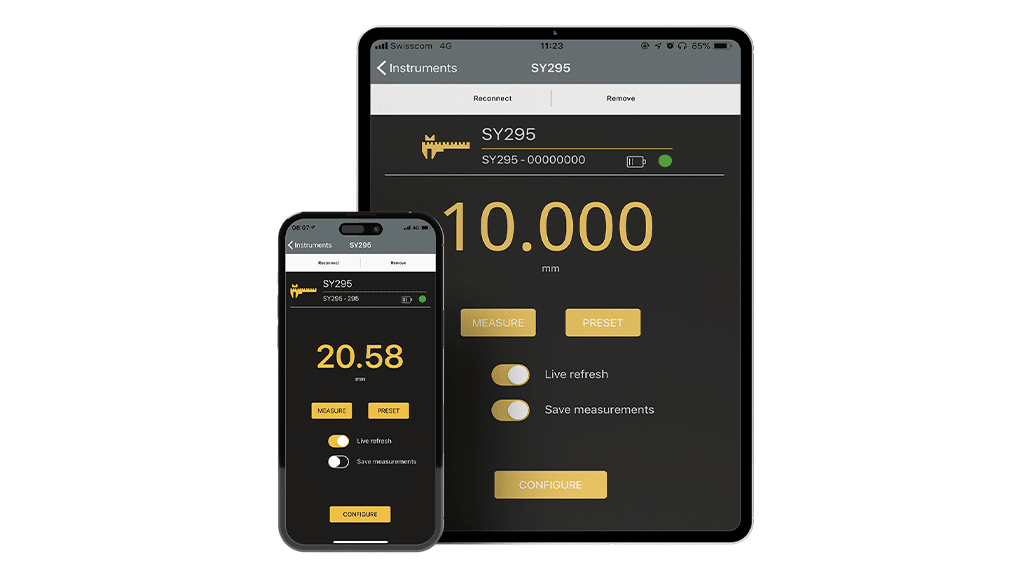

At Sylvac, we take pride in delivering exceptional metrology instruments that are synonymous with quality, durability, and precision. Our instruments utilize ultra-low power consumption, allowing for extended battery life. This means you can perform continuous quality control without frequent interruptions to change batteries. We prioritize efficiency and productivity, empowering you to maintain a steady workflow during the inspection process.

Customizable Control Plans with Sylcom

Sylcom, our advanced software, is specifically developed for Sylvac’s dimensional quality control instruments. However, it goes beyond traditional dimensional checks by offering the flexibility to incorporate non-dimensional measures directly into the control plans. This means you can easily add visual verifications, operator input, or any other required non-dimensional checks. With Sylcom, your control plans become fully customizable, allowing you to create comprehensive step-by-step guides tailored to your specific inspection requirements.

Advantages of Customizable Control Plans :

By leveraging Sylvac’s customizable control plans, you unlock several advantages that enhance your final inspection process.

Firstly, these plans aid in decision-making by providing a systematic and structured approach to inspection. Each step is clearly defined, ensuring that no crucial aspect is overlooked or skipped, contributing to the overall quality of the inspected parts.

Secondly, the inclusion of non-dimensional measures, such as visual verifications and operator input, adds another layer of assurance, reinforcing the thoroughness of the inspection process.

Finally, Sylvac’s customizable control plans promote traceability in every aspect of the final inspection. By capturing and recording data from both dimensional and nondimensional checks, you create a comprehensive record that facilitates traceability throughout the manufacturing and quality control processes. This traceability is crucial for audits, compliance with regulations, and product recalls, enabling you to swiftly identify and address any issues that may arise.