In today’s manufacturing landscape, automation has become a catalyst for increased efficiency and productivity. At Sylvac, we recognize the significance of integrating quality control seamlessly into automated production processes. Our automation-ready solutions provide you with a unique advantage by effortlessly integrating precise quality control instruments into your assembly line. With Sylvac’s automation-ready solutions, you can achieve real-time quality control at every step, streamline operations, ensure consistent product quality, and drive efficiency to new heights. Discover how Sylvac’s automation-ready solutions elevate your production, where quality control meets seamless automation.

1. Streamlined Integration for Enhanced Efficiency

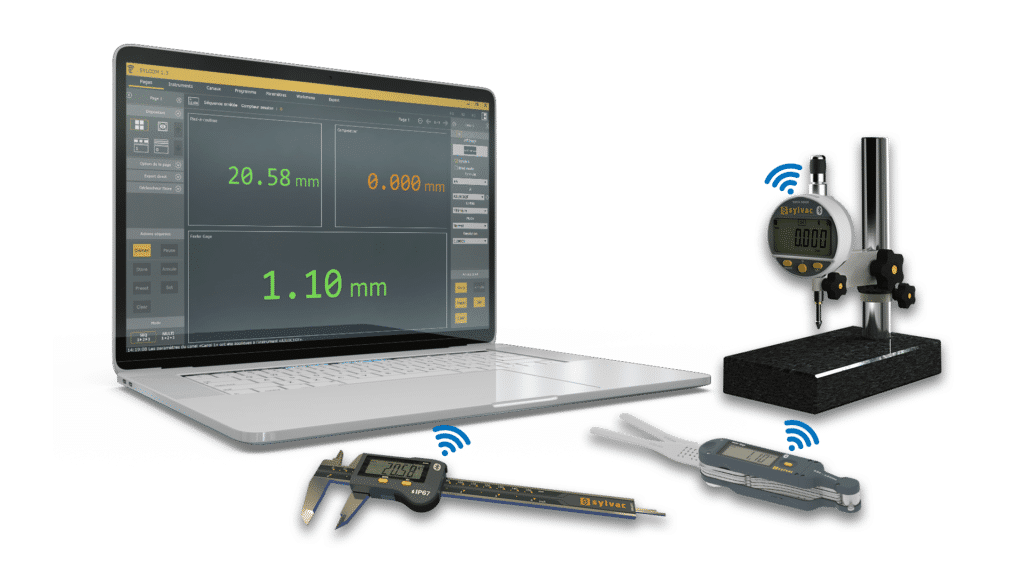

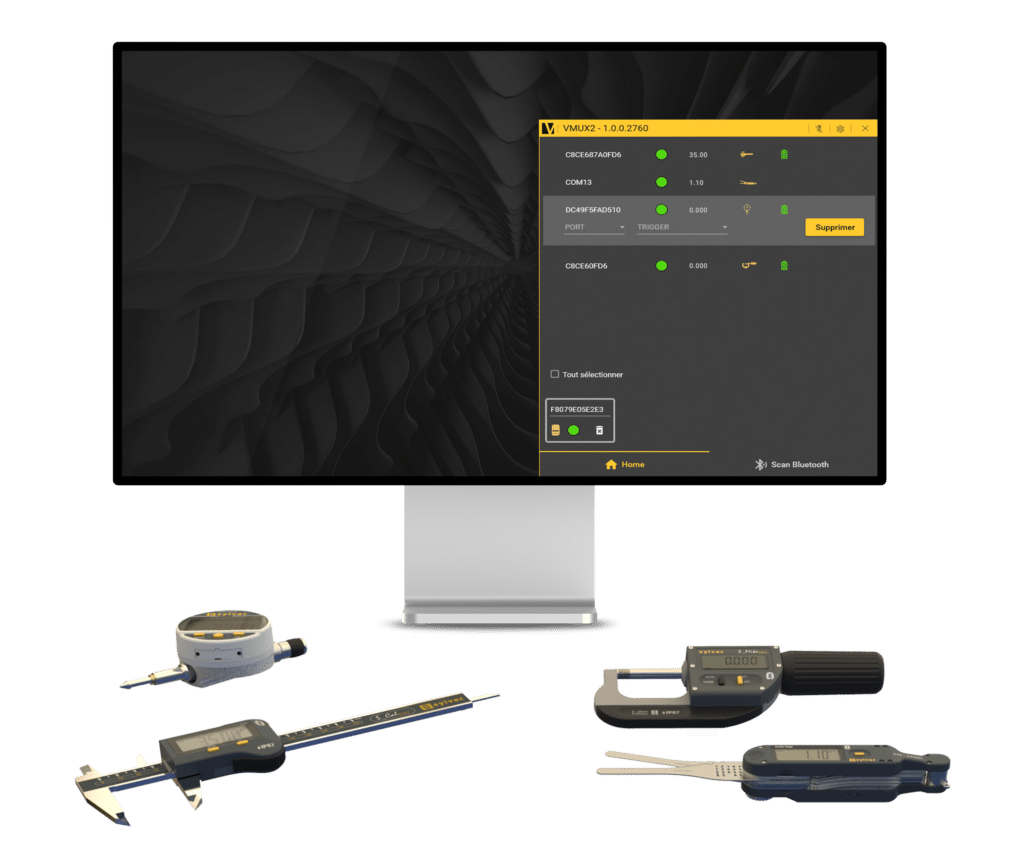

Sylvac’s automation-ready solutions offer the unrivaled benefit of seamless integration with your automated production processes. Our Sylcom software, communicating via OPC UA, enables you to effortlessly incorporate our Scan machines into your production workflow. By seamlessly integrating quality control instruments into your assembly line, you can achieve real-time monitoring and optimization. This streamlined integration minimizes disruptions, eliminates manual intervention, and maximizes the efficiency of your production line.

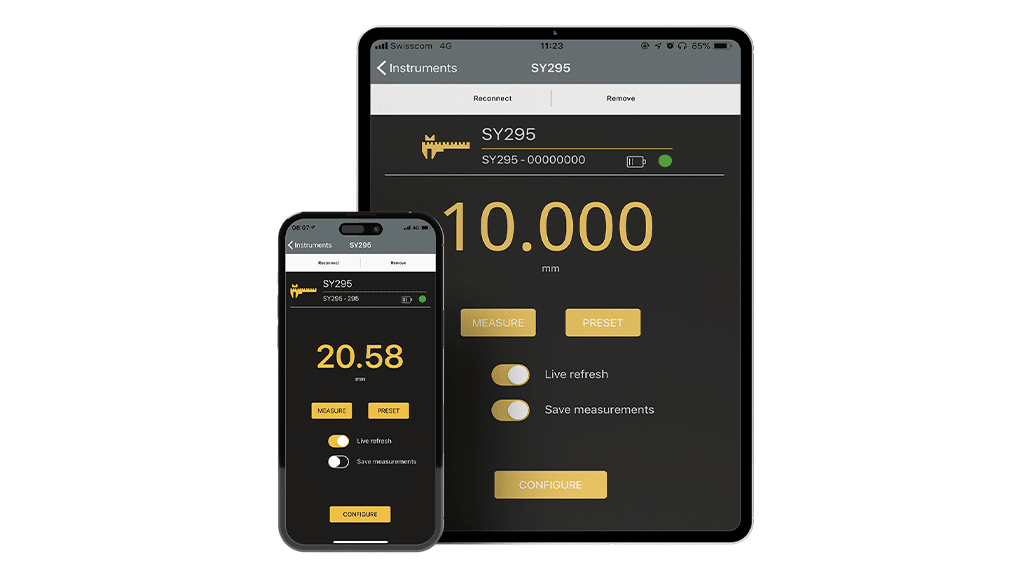

2. Real-Time Quality Control at Every Step

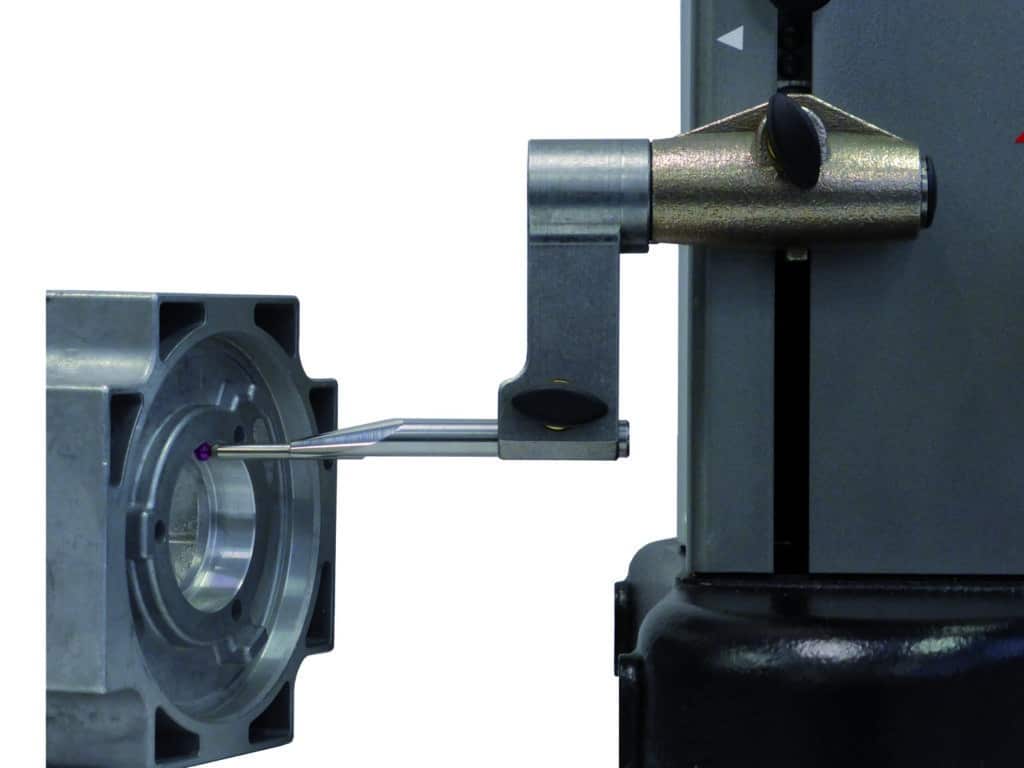

With Sylvac’s automation-ready solutions, you gain the advantage of real-time quality control throughout your automated production process. Our integrated Scan machines deliver precise and reliable measurements, ensuring the consistency and accuracy of your products. By incorporating quality control instruments directly into your assembly line, you can proactively monitor and adjust parameters, identify deviations, and make immediate corrections, all in real-time. This real-time quality control capability guarantees that every product meets the highest standards of quality and performance.

3. Ensuring Consistent Product Quality

Integrating Sylvac’s quality control instruments into your automated system significantly contributes to maintaining consistent product quality. By incorporating our automation-ready solutions, you minimize the risk of defective products, reduce waste, and enhance customer satisfaction. Real-time quality control ensures that every item that passes through your assembly line adheres to stringent quality standards, resulting in superior product performance and a stronger market reputation.

4. Driving Efficiency and Productivity

Seamlessly integrating quality control into your automated production processes with Sylvac’s automation-ready solutions drives overall efficiency and productivity. By eliminating manual measurement steps and incorporating precise instruments directly into the assembly line, you save valuable time and resources. Automated quality control reduces human error, speeds up production cycles, and enables you to meet increased production demands with ease. The result is enhanced operational efficiency, optimized throughput, and improved profitability.